01

ABOUT

ECAD Services operate within the engineering projects environment since 2007.

ECAD is focused on finding the right person for the right role.

This is by opening the employment opportunities to anyone and everyone and assessing their capability.

Once the capability is known we then look at how to make that resource available.

We also recognise the importance of young engineers; we plan to develop these engineers by utilising our experienced engineers as group mentors.

For more details see our Success on Recruitment.

UK engineering heritage was classed as one of the world leaders, this was due to the industrial revolution, wherever industry was created local engineering companies evolved.

These early engineering companies created their own standards, inventing unique and ground-breaking methods to solve problems, providing the UK with a vast amount of experience.

Some of the overseas companies replicated our manufacturing industries, however, because their local engineering companies did not evolve in the same manner, then some of their copied items although cheaper were substandard.

Some of these oversea companies recognised these substandard issues and so created problem-solving tools for non-engineers to resolve their issues.

Over the past 30 years, the engineering resource level in the UK industry has been slowly declining, this is due to many factors, such as;

• Improvements in hardware & software technology

• Improvements in manufacturing techniques

• Loss of manufacturing industry overseas

• Cost-saving projects (headcount reduction)

• Lack of recruitment and development of young engineers

ECAD has noticed that the headcount reduction initiatives as also indirectly effecting engineering project practices, for example, an engineering projects office would have had designers, purchaser, clerk of works, accountant, etc… these tasks are now generally carried out by the projects engineer which means they are now carrying out c.20% engineering c.80% administration.

Now due to the lack of engineering experience, some of the UK industry has adopted these oversea problem-solving techniques so non-engineers can resolve issues, however from experience if an engineer is not present at these problem-solving reviews then the output could be inconclusive.

For every £1 spend on investment projects £1.3 is gain on UK GDP

Institute For Fiscal Studies

Investment Potential

02

SERVICE

ECAD provides capable engineering resources to assist in delivering capital investments.

01.

SAFETY FIRST

By using the correct communication tools to liaise with all involved in the project we plan the works to reduce the risks by co-operating and co-ordination, using the right people for the right job at the right time.

02.

Idea Validation

Our target is to be +/- 50% on capital investment and benefit realisation.

To do this we develop:

• Technical Design Brief

• Low level engineering drawings (layouts, flow diagram)

• Basic cost of investment

• Benefit identification

• Rate of return accountancy document

03.

Feasibility Engineering

Also, further engineering detail is carried out to understand full scope and compliance requirements.

The output from this study is to gather enough information to target an accuracy +/- 25% on capital investment and benefit realisation.

04.

Pre-Engineering

This is to focus on gathering as much information as possible to develop a capital application of +/-10% accuracy.

This could include specific equipment identification, process diagrams, layouts, schedules, building compliance, planning permission, along with costs for equipment, build and services.

05.

Project management / Planning

06.

Process engineering

07.

Mechanical engineering

08.

Civil And Structural engineering

09.

Electrical engineering

10.

Instrumentation & Automation

11.

Construction Design Management (CDM)

ECAD can act as Principle designer, principle contractor and advisor to client to make sure that the design complies with all current legislation and is;

• Fit to design

• Fit to install

• Fit to maintain

• Fit to remove at end of life

12.

Installation Supervision

With over 200 years of collective experience managing installations, demolitions & rebuilds in live plants, working with multi disciplines across multiple industries. Previous works include isolation and separation of paper machines from live site and eventual demolition with no impact to running business.

13.

System Risk Assessments

ECAD has develop a SMART document which allows the team to carry out a risk assess on a capital investment in line with CE Requirements.

The completed document identifies gaps to be actioned by either physical intervention or management controls.

This allows us to handover a project in confidence.

14.

Compliance (ATEX, PUWER, CE)

15.

Commissioning

16.

Training

17.

Standardisation & SMART Documents

ECAD have developed our own standards and SMART documents which focuses on efficiency, simplicity and continuity.

These structures allow us to introduce new member quickly and with minimum effort.

We are constantly focusing on value added techniques.

18.

Problem Solving

ECAD utilise root cause analysis techniques such as;

• CEDAC (Fishbone)

• Kaizen (continuous improvements)

To Define, Measure, Analyse, Improve, Control (DMAIC)

19.

ECAD Work Package

The purpose of the work package is to focus on skills and efficiency.

The ECAD Work Packages will be posted on the “Job Portal”

The work packages are designed in line with IR35 regulations.

20.

Looking to the Future

At ECAD we are constantly reviewing how to improve our delivery techniques.

We are particularly excited to see the development of Microsoft’s HoloLens 2.

We are in the process of utilising our own HoloLens 2 headsets to aid with equipment commissioning, handover training, problem-solving, and remote access to Subject Matter Experts who are overseas.

03

PROJECTS

CLICK BELOW FOR FURTHER DETAILS ON SOME OF OUR RECENT PROJECTS

04

PEOPLE

The way we work is changing. ecad are creating enabling structures

The majority of the industry is currently being managed by Generation X, followed by Millennials, followed by Baby Boomers. Within the next 10 years it is predicted that there will be more Millennials managing business than Generation X.

ECAD Blog

Industry Insights

05

Success

ECAD have successfully grown its business, we believe this growth is directly related to our approach on ensuring the business remains simple, sustainable, scalable and value added.

MICROSOFT HOLOLENS

• Instant visual and audio support (Remote Assist)

• On site virtual reality of CapEx investment (1 to 1 scale)

ECAD Work Package (EWP)

• Reduced admin & maximise output

• Cost saving competitive bidding (IR35 Compliance)

SMART Documents

(Project Management, Engineering, Compliance & Purchasing)

• Saving cost & time

• Zero extras

Office in the Cloud

• Reduction in travel cost for travel expenses

• System security for remote working and file storage

Recruitment

• Large pool of resource

• Flexible working

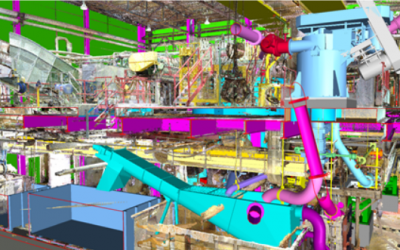

3D Laser Scanning

• Ease of operation (standard PC)

• Improve accuracy (full overall visibility leading to no site modifications)

• Efficiency (full site surveying in hours not weeks)