3D LASER SCANNING

The majority of the Capital investments ECAD has worked on have been on “Brown-Field” sites.

The majority of the Capital investments ECAD has worked on have been on “Brown-Field” sites.Since the early 1990’s the standard approach to survey a Brown-Field site was to use tape measures, levels and theodolite, then draw up the survey on to a CAD system.

During this time there been available 3D Laser Scanning surveying systems were available, however the cost to hire or buy them was high, and the software along with the processing power required very costly.

However, over the last 3 years the technology of the scanning units has improved in technology and the software to patch the scans together is has come down in price dramatically to around c.£50 per month, in addition the processing power required is now available on a standard laptop.

Experience;

We used a Faro 3D laser scanner for 3 days (hire cost c.£500/day).

The number of scans taken was 20 location per day.

It took 3 days to patch the images together and check on AutoCAD ReCap (monthly cost c.£50/month)

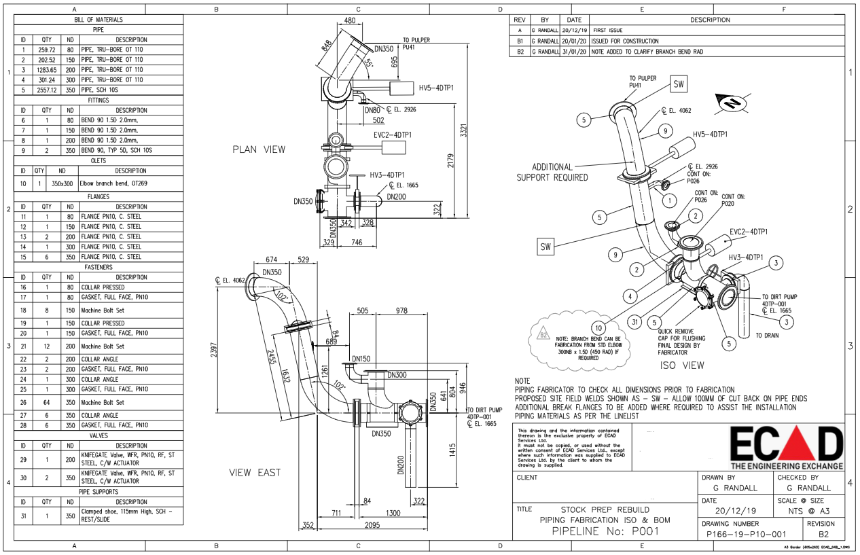

We then imported the Point Cloud into AutoCAD 3D Plant design.

After generating the new 3D plant layout, we then exported from the cloud into AutoCAD Navisworks (free software)

The Navisworks software was used in design reviews on site and on Teams meetings (across the internet), which was commented by the client as excellent.

The output drawings from AutoCAD Plant Design, proved accurate to +/- 5mm, with the pipework fabricator commenting on how there were virtually no clashes, requiring minimum changes on site. We also noticed that there was a lot of 100mm pipe cuts on the floor; this is a site weld where we include an additional 100mm in Z, Y, & Z to ensure we account for site installation complications.

In summary this plant design success could not have been achieved without using a 3D Laser Scanner.

3D Laser Scanning has proved very cost effective, very accurate, and very easy to operate.

The output drawings from AutoCAD Plant Design, proved accurate to +/- 5mm, with the pipework fabricator commenting on how there were virtually no clashes, requiring minimum changes on site. We also noticed that there was a lot of 100mm pipe cuts on the floor; this is a site weld where we include an additional 100mm in Z, Y, & Z to ensure we account for site installation complications.

In summary this plant design success could not have been achieved without using a 3D Laser Scanner.

3D Laser Scanning has proved very cost effective, very accurate, and very easy to operate.

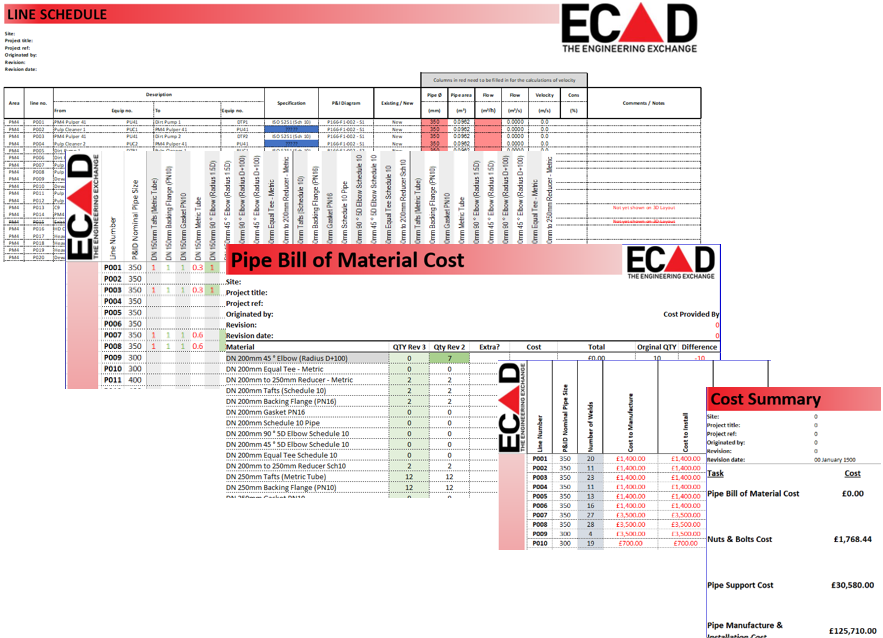

Our project bespoke SMART document includes such items as:

• Pipe Schedule

• Request for Quotation

• Bid Analysis

• Change Management

The SMART document deliverables were:

• 4 Quotes within 10% High to Low

• Contract c.£350k

• Waste Material less than 150kg

• Zero Extras to Contract